In the realm of technological innovation companies like GeT Cameras have played a pivotal role in shaping the landscape of machine vision cameras. These sophisticated devices play a pivotal role in diverse industries, from manufacturing and healthcare to automotive and beyond. Let’s delve into the intricacies of machine vision cameras, exploring their applications, underlying technologies, and the transformative impact they have on various sectors.

Understanding Machine Vision

Machine vision is a multidisciplinary field that combines computer science, optics, and image processing to enable machines to interpret and understand visual information. At the heart of this technology are machine vision cameras, which serve as the eyes of the system, capturing images and videos for subsequent analysis. Unlike human vision, machine vision is driven by precision and speed, making it ideal for tasks that demand accuracy and efficiency.

Applications Across Industries

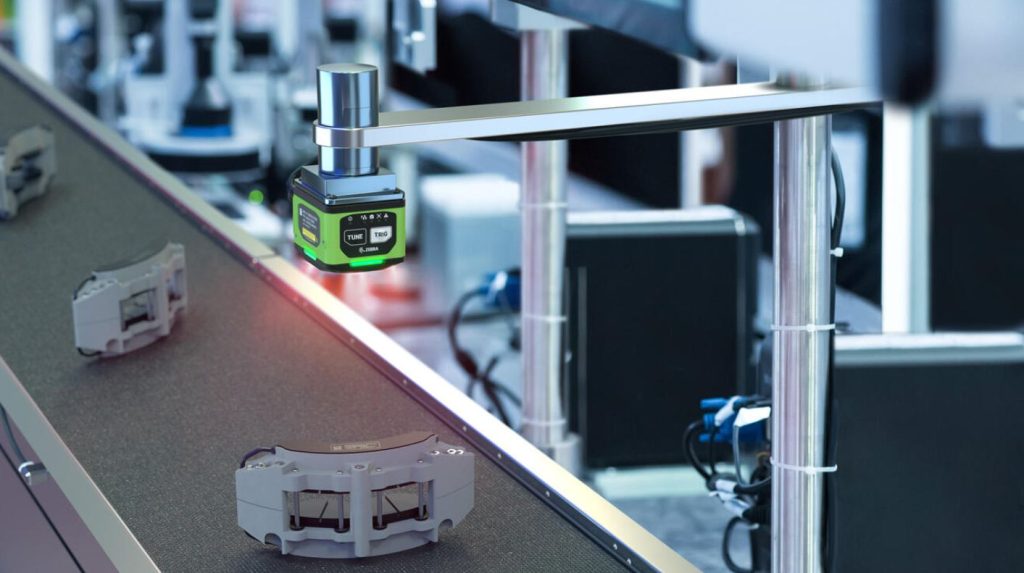

1. Manufacturing and Quality Control:

Machine vision cameras are extensively used in manufacturing for quality control and inspection purposes. They can identify defects, measure dimensions, and ensure products meet stringent quality standards. This enhances efficiency and reduces the likelihood of defects reaching the end consumer.

2. Healthcare:

In healthcare, machine vision cameras play a crucial role in medical imaging, diagnostics, and surgery. They contribute to tasks such as detecting anomalies in X-rays, assisting in robotic surgeries, and even monitoring patient vital signs through computer vision applications.

3. Automotive:

The automotive industry benefits from machine vision cameras for various applications, including driver assistance systems, lane departure warnings, and automated parking. These cameras contribute to the development of autonomous vehicles, enhancing safety and efficiency on the roads.

4. Retail and Logistics:

In retail, machine vision cameras are employed for inventory management, tracking merchandise, and enhancing the overall shopping experience. In logistics, these cameras facilitate the automation of sorting and tracking packages, improving the speed and accuracy of order fulfillment processes.

5. Agriculture:

Precision agriculture leverages machine vision to optimize crop management. Cameras mounted on drones or agricultural machinery can monitor crop health, detect diseases, and assist in targeted pesticide application, leading to more sustainable and efficient farming practices.

Key Technologies Driving Machine Vision Cameras

1. Image Sensors:

Image sensors are fundamental components of machine vision cameras. CMOS (Complementary Metal-Oxide-Semiconductor) and CCD (Charge-Coupled Device) sensors are commonly used, each with its own advantages. CMOS sensors are known for low power consumption and rapid data readout, while CCD sensors often excel in low-light conditions.

2. Optics:

The lenses used in machine vision cameras are designed to capture clear and sharp images. The choice of optics depends on the specific application, considering factors such as focal length, field of view, and depth of field.

3. Image Processing:

Advanced image processing algorithms are employed to analyze the data captured by machine vision cameras. This includes tasks such as object recognition, pattern matching, and image enhancement. The integration of artificial intelligence and machine learning further enhances the capabilities of these systems over time.

4. Connectivity and Integration:

Machine vision cameras are often part of larger systems and networks. Connectivity options, such as Ethernet and USB, facilitate seamless integration into manufacturing lines, robotic systems, or other applications. This connectivity enables real-time data transfer and remote monitoring.

Challenges and Future Trends

While machine vision cameras have significantly advanced, challenges persist. Overcoming issues related to image quality, environmental variability, and the complexity of real-world scenarios remains an ongoing focus. Additionally, ethical considerations related to privacy and data security must be addressed as these technologies continue to evolve.

Looking ahead, the future of machine vision cameras holds exciting possibilities. The integration of 3D imaging, hyperspectral imaging, and the continued evolution of artificial intelligence are poised to further expand the capabilities of these systems. As technology continues to progress, machine vision cameras will likely become even more versatile, contributing to advancements in automation, safety, and the overall efficiency of various industries.

In conclusion, machine vision cameras stand at the forefront of the technological landscape, reshaping how we perceive and interact with the world. As these devices continue to evolve, their impact on industries and everyday life is set to grow, ushering in a new era of precision, efficiency, and innovation.